Engineers have made a groundbreaking discovery in wastewater treatment. They have developed a revolutionary membrane that can effectively separate chemicals from wastewater, allowing for their reuse. This not only improves sustainability but also enables industries to extract valuable by-products and chemicals from wastewater.

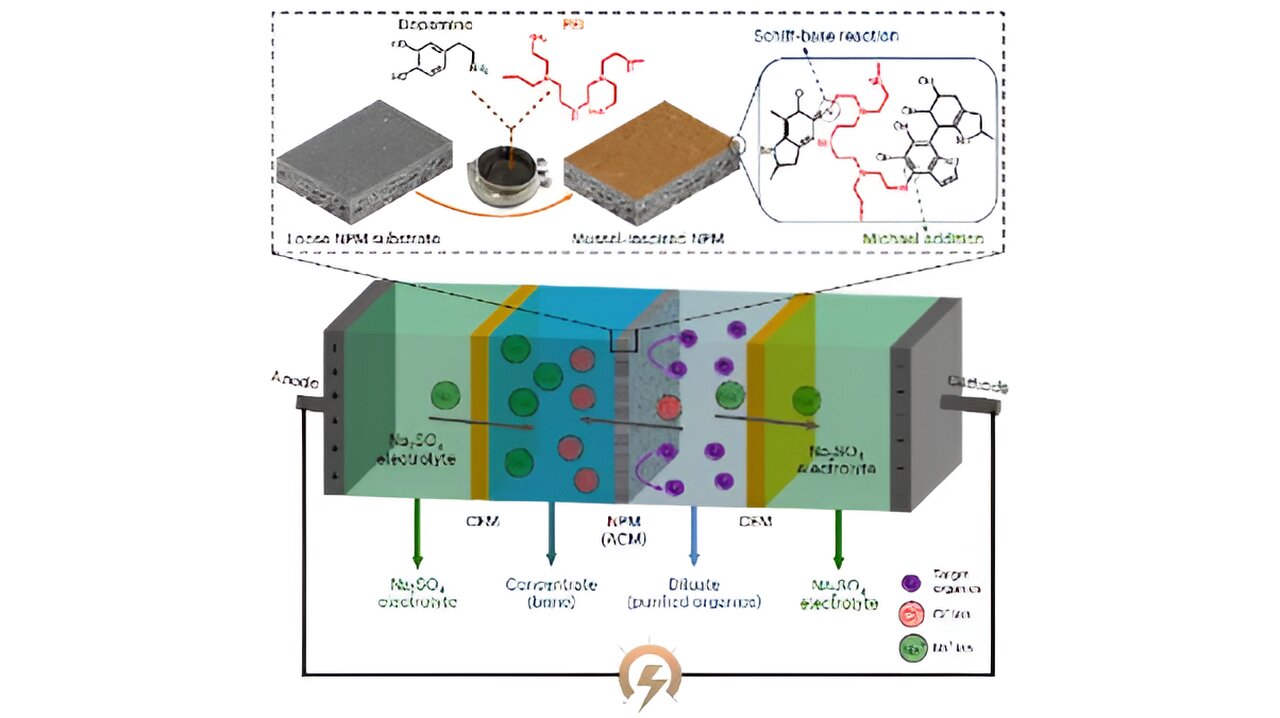

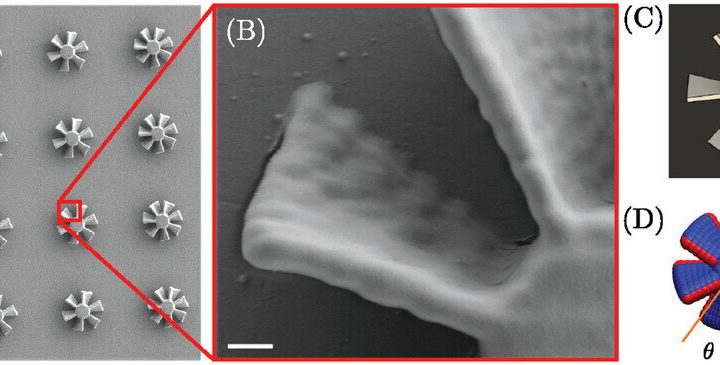

Created specifically for wastewater treatment, this thin-film composite nanoporous membrane, known as a TFC NPM, has an “unprecedented” ability to separate salts and other chemical components from water. Its unique properties, inspired by mussels, have the potential to revolutionize water management in industries such as pharmaceuticals, oil and gas, textiles, and food processing. The membrane could replace current equivalents used in electrodialysis, a process that treats water by transporting ions through membranes under an electrical current. Unlike existing membranes, the TFC NPM is more efficient, achieving separation efficiencies of over 99% while using less energy and at a lower cost.

Dr. Ming Xie, a Chemical Engineering lecturer at the University of Bath and one of the authors of the research paper published in Nature Water, believes that this membrane could change the way we think about wastewater treatment. He states, “Traditionally, many industries have seen their wastewater as a necessary cost of business. Technologies like the membrane we have developed can help us reduce carbon emissions by lowering the energy requirement for wastewater treatment. Additionally, we can efficiently separate and reuse valuable components such as chemicals, salts, energy, biomass, and nutrients, turning them into high-value by-products.”

The researchers drew inspiration from mussels when designing the coating on the membrane surface. The coating, made up of the polymers polyethyleneimine (PEI) and polydopamine (PDA), mimics the stickiness of mussels, allowing water to pass through while blocking other compounds and organic materials. This innovative approach improves water filtration and enables highly efficient and low-energy separation of chemicals.

During tests, the researchers demonstrated the membrane’s exceptional performance by successfully removing antibiotics from saltwater solutions. The membrane achieved over 99.3% desalination efficiency and over 99.1% recovery of the antibiotics. If implemented in industrial wastewater treatment, this membrane has the potential to outperform existing processes in effectively separating various organic/NaCl mixed solutions.

The authors of the research paper are now exploring avenues to commercialize this groundbreaking membrane.