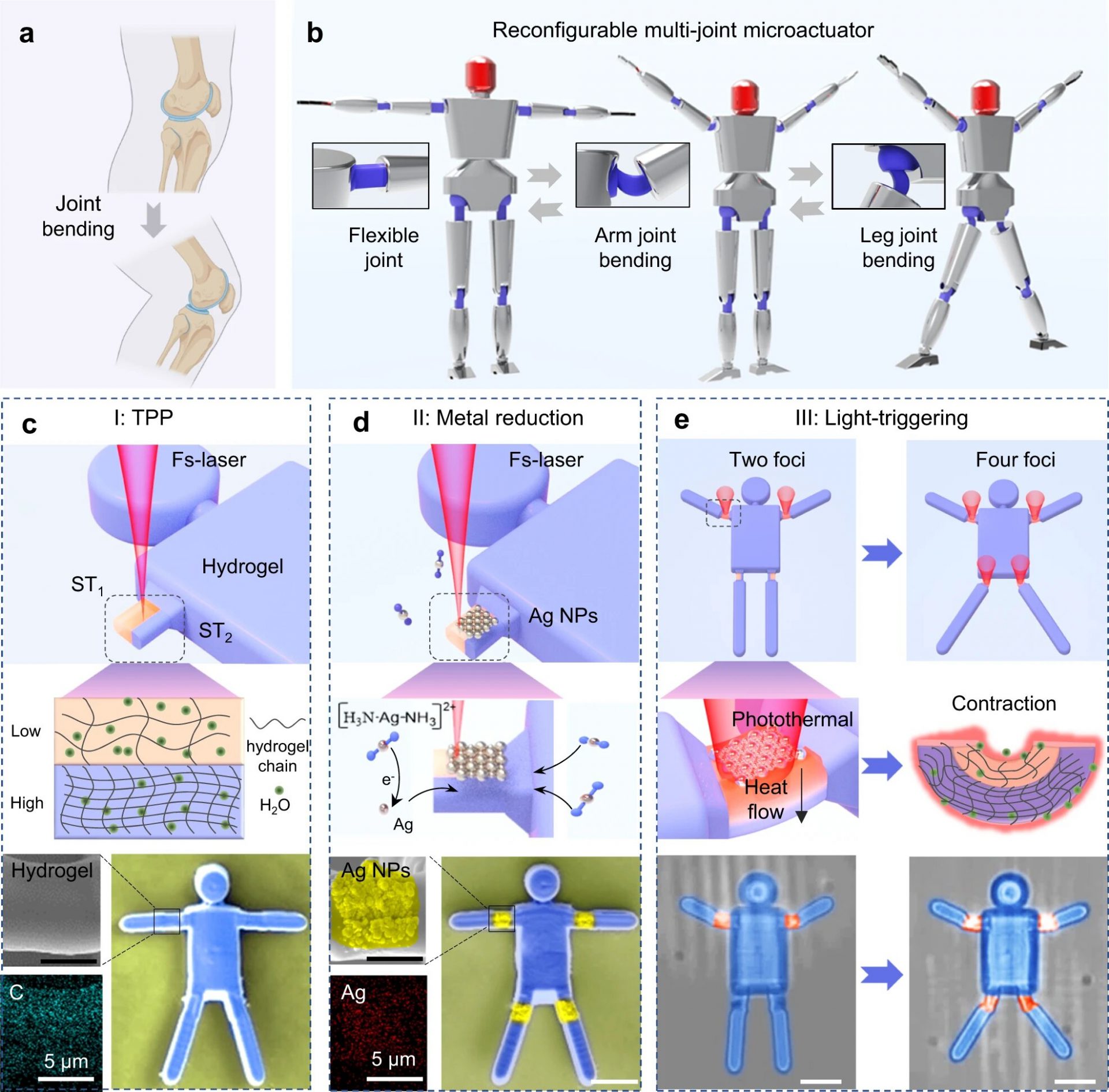

A groundbreaking research team, led by Prof. Wu Dong from the University of Science and Technology of China (USTC) of the Chinese Academy of Sciences (CAS), has introduced an innovative femtosecond laser 2-in-1 writing multi-material processing strategy. This strategy allows for the fabrication of micromachined joints composed of temperature-sensitive hydrogels and metal nanoparticles. The team has successfully developed multi-jointed humanoid micromachines with over 10 different deformation modes. These remarkable findings have been published in Nature Communications.

In recent years, femtosecond laser two-photon polymerization has emerged as a cutting-edge technique for three-dimensional fabrication with nanoscale precision. It has been widely utilized in the production of various functional microstructures, showing immense potential in fields such as micro-nano optics, microsensors, and microelectromechanical systems. However, the challenge lies in leveraging femtosecond lasers for multi-material processing and constructing micro-nano mechanics with multiple modalities.

In this study, the research team employed a femtosecond laser dual-function fabrication strategy. They utilized asymmetric two-photon polymerization to create hydrogel joints and locally deposited silver nanoparticles (Ag NPs) within the joints through laser reduction. This technique induced anisotropy in cross-linking density within specific areas of the hydrogel micro-joints, enabling directional and angular-controllable bending deformations.

The precise fabrication of silver nanoparticles on the hydrogel joints was achieved through in-situ laser reduction deposition. These nanoparticles exhibited strong photothermal conversion effects, resulting in ultra-fast response times (30 ms) and extremely low driving power for the multi-joint micromachinery. The team integrated eight micro-joints into a humanoid micro-mechanism and utilized spatial light modulation technology to stimulate each micro-joint precisely in 3D space.

The collaborative deformation between multiple joints allowed the humanoid micromachine to achieve various reconfigurable deformation modes, leading to mesmerizing “dancing microrobots” at the micrometer scale. As a proof of concept, the team designed a dual-joint miniature mechanical arm capable of collecting micro-particles in both parallel and divergent directions by controlling the distribution and deformation direction of the micro-joints.

This femtosecond laser dual-function fabrication strategy opens up possibilities for constructing deformable micro-joints in various 3D micro-structured areas, enabling multiple reconfigurable deformation modes. In the future, micromachinery with diverse deformation modes will revolutionize applications such as micro-goods collection, microfluidic manipulation, and cellular operations.