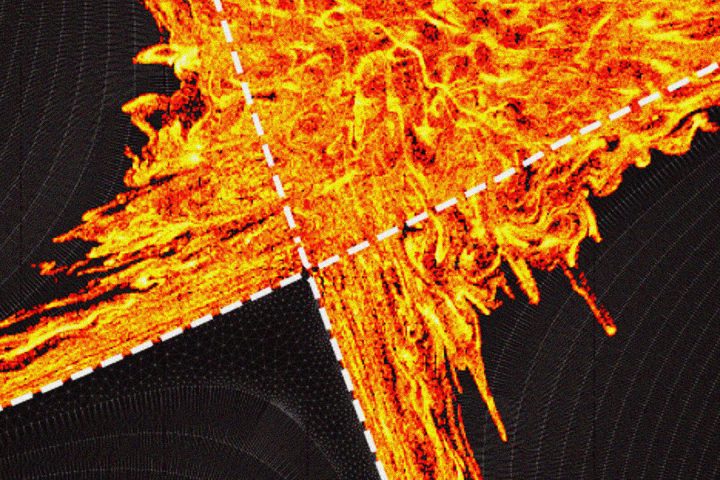

Did you know that only about 9% of plastic in the United States is actually recycled? That means a lot of plastic, including flexible films and colored plastics, ends up in landfills. But now, chemical engineers at the University of Wisconsin–Madison have developed a groundbreaking technique to turn low-value waste plastic into high-value products.

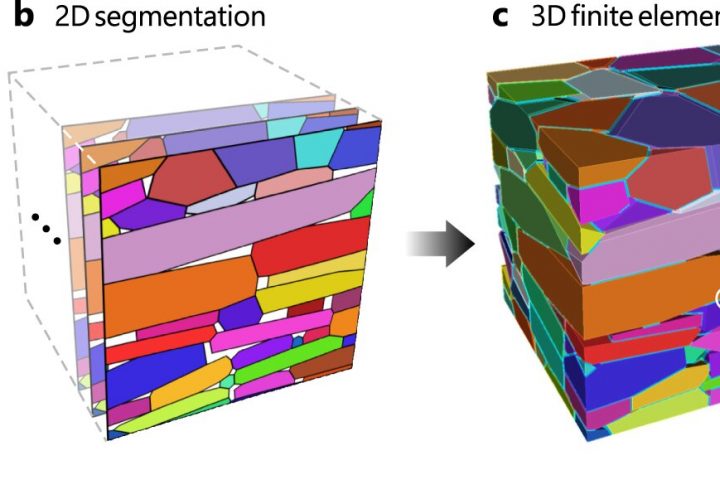

This new method, described in the journal Science, not only increases the economic incentives for plastic recycling but also has the potential to reduce greenhouse gas emissions by 60%. The technique combines pyrolysis, a process of heating plastics to high temperatures in an oxygen-free environment, with homogenous hydroformylation catalysis, a less energy-intensive chemical process.

The result is the production of high-value materials, such as aldehydes and industrial alcohols, which can be used to make a wide range of products, including soaps, cleaners, and polymers. This technology has the potential to revolutionize the plastic recycling industry and provide a more sustainable and lucrative way to use waste plastics.

The study was a collaborative effort across different departments at UW–Madison, with experts in chemistry, chemical and biological engineering, and economics working together to develop and analyze the technique. The next step for the team is to further refine the process and explore different combinations of recycled plastics and catalysts to optimize the production of final chemical products.

“There’s a huge market for the products we’re making. I think it really could change the plastic recycling industry,” says George Huber, the professor leading the research.