Did you know that producers of infant formula go to great lengths to ensure its safety? They employ comprehensive food safety systems, including product testing. But here’s the interesting part: a recent study from the University of Illinois Urbana-Champaign reveals that not all testing methods are equally effective at catching contaminants.

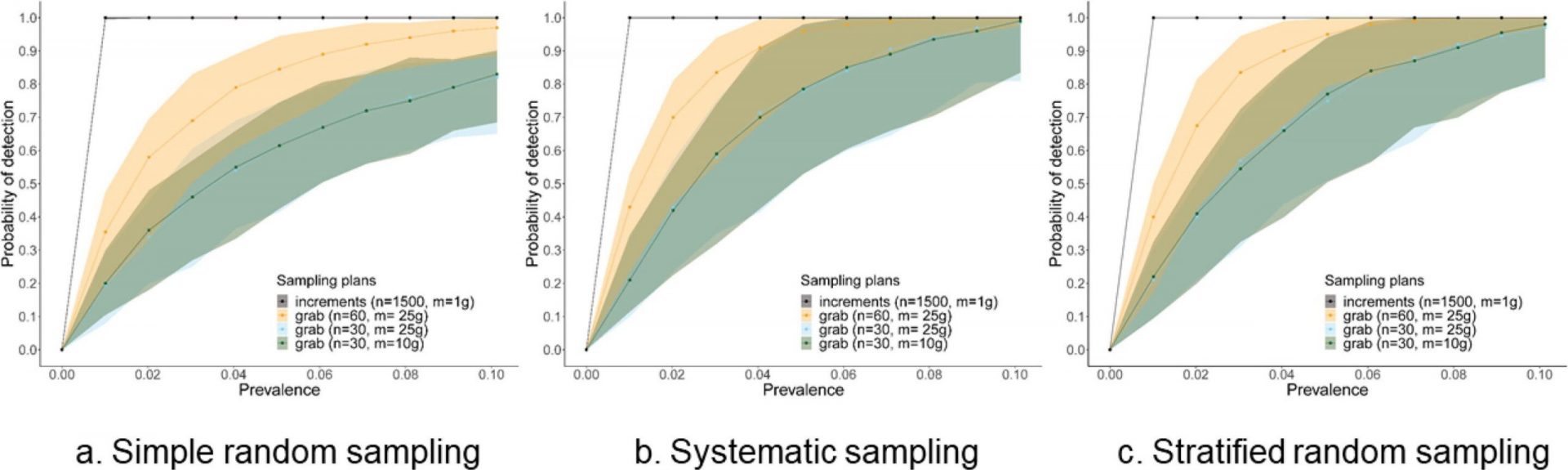

According to the researchers, spacing out samples over time in a stratified sampling pattern is better at detecting risky pathogens like Cronobacter than randomly sampling during production. They also discovered that while increasing the number of samples generally improves safety, there’s a point where it becomes unlikely to increase the effectiveness of testing.

“Our findings demonstrate the power of existing sampling and testing guidance, at least for the specific hazard profile we studied,” said Matthew J. Stasiewicz, the project lead and associate professor in the Department of Food Science and Human Nutrition at the University of Illinois Urbana-Champaign.

However, Stasiewicz emphasized the need for further research and data sharing to better understand contamination patterns in infant formula production. This knowledge would enable sampling and testing to be better tailored to current needs.

Producers of infant formula already have safety systems in place, such as milk pasteurization and measures to prevent contamination. Product testing serves as an additional tool to ensure safety, but it must be powerful enough to catch any major failures before potentially risky products reach customers.

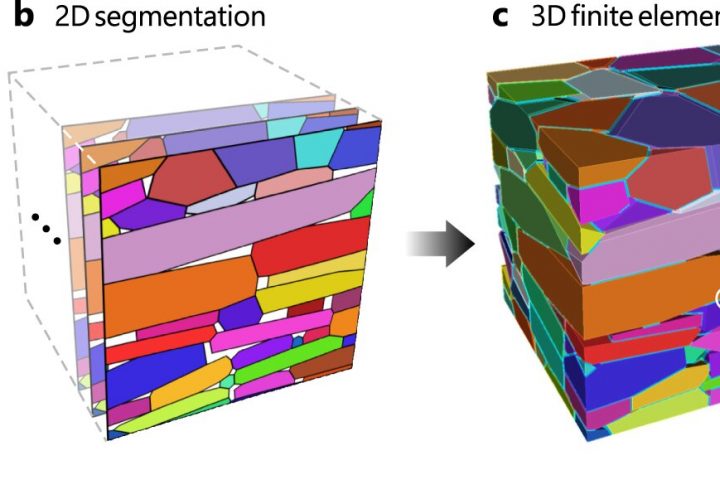

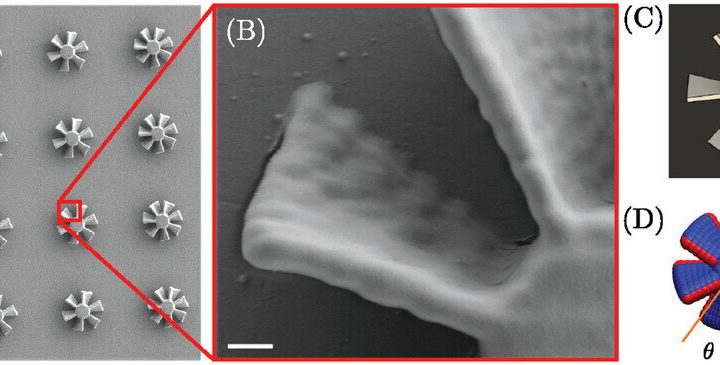

The study, published in the Journal of Food Protection, received support from the Institute for the Advancement of Food and Nutrition Sciences (IAFNS) Food Microbiology Committee. The researchers used computer models to simulate sampling and testing of finished formula, evaluating the effectiveness of current national and international testing guidelines and suggesting improvements.

By analyzing samples from Cronobacter-contaminated batches produced in Europe, the researchers determined that safety plans with 30 or more grab samples had a high probability of detecting hazards. However, they also found that systematic or stratified random sampling patterns are more effective than simple random sampling for bulk powder testing.

To help industry stakeholders gain a deeper understanding of sampling effectiveness, the researchers developed a web app that allows them to simulate various sampling scenarios specific to their plants. This knowledge empowers producers to proactively address risks and optimize their current sampling practices.

If you’re a concerned parent worried about bacterial contamination in formula, it’s best to consult your doctor for safer feeding options. For instance, using hot water during reconstitution and then cooling it to body temperature can significantly reduce the risk of Cronobacter contamination, as suggested by an international risk assessment. However, it’s important to handle heated bottles with care to prevent burns.