A team of brilliant scientists from Ames National Laboratory and Texas A&M University has revolutionized the prediction of metal ductility. Using a cutting-edge quantum-mechanics-based approach, they have developed an inexpensive and efficient way to forecast ductility. Their groundbreaking research focused on refractory multi-principal-element alloys, which are materials with immense potential for applications in aerospace, fusion reactors, and land-based turbines, but often lack the necessary ductility for these purposes.

Ductility is a crucial property that determines a material’s ability to withstand physical strain without cracking or breaking. According to Prashant Singh, the leader of the theoretical design efforts at Ames Lab, there is currently no reliable method to predict metal ductility. The traditional trial-and-error approach is not only expensive and time-consuming, but also impractical in extreme conditions.

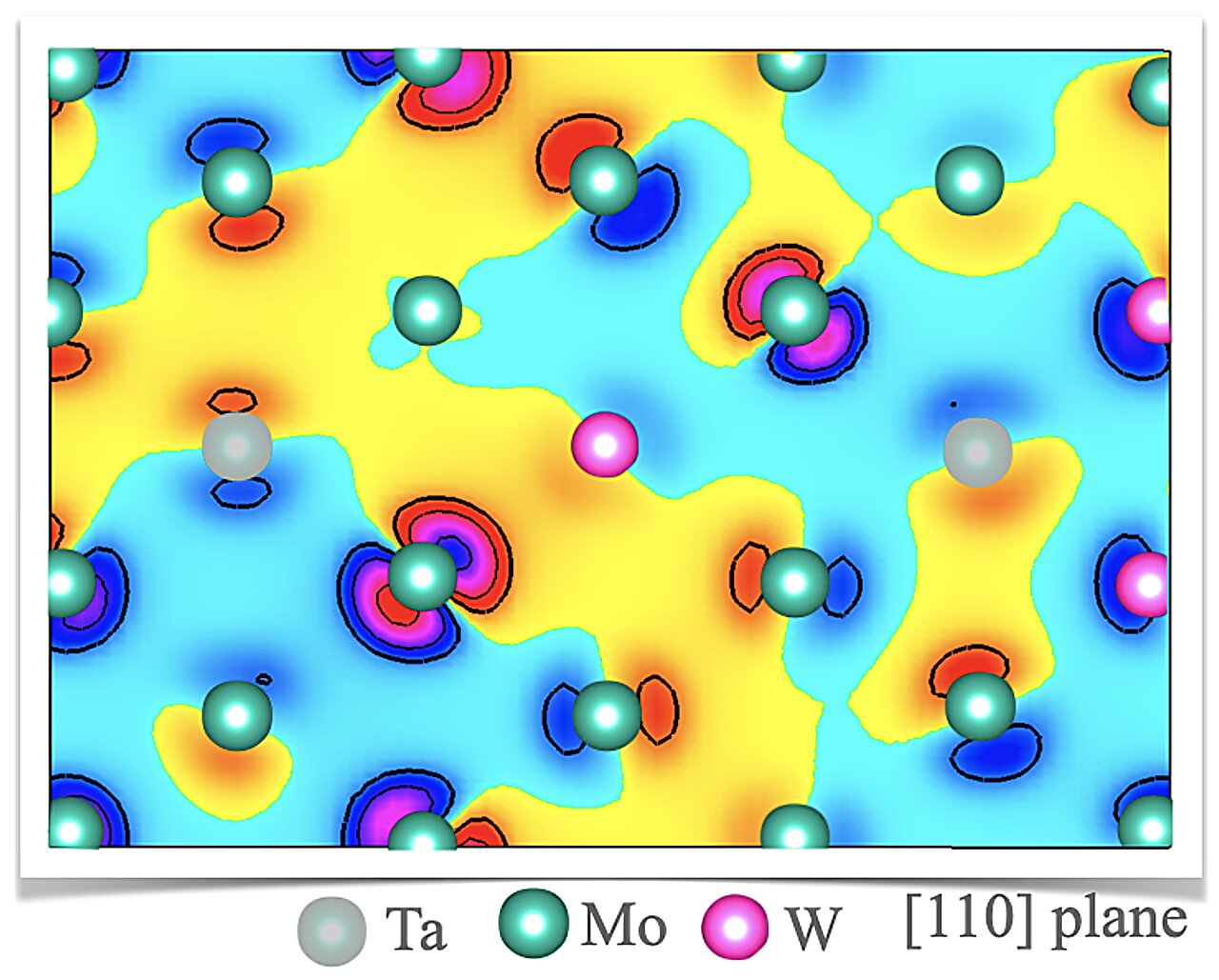

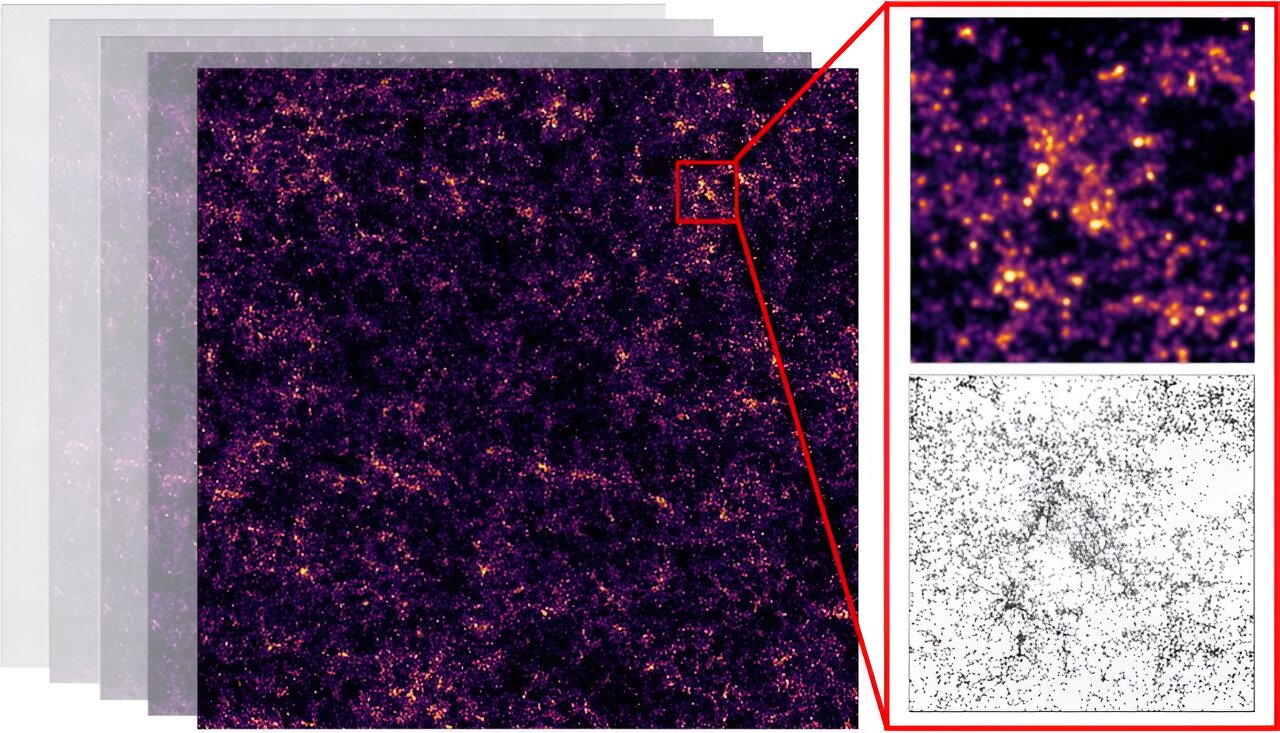

In the past, atoms were modeled as rigid spheres with symmetrical properties. However, Singh explains that real materials consist of atoms with different sizes and shapes. When these atoms are mixed, they continuously adjust to fit within a fixed space, resulting in local atomic distortion.

The new analysis takes into account this local atomic distortion to determine whether a material is brittle or ductile. It surpasses the capabilities of existing approaches by capturing non-trivial details. Singh states, “Current approaches are not very efficient at distinguishing between ductile and brittle systems for small compositional changes. But the new approach can capture such details because we have added a quantum mechanical feature that was missing.”

Another remarkable advantage of this high-throughput testing method is its efficiency. Thousands of materials can be rapidly tested, enabling the prediction of promising material combinations for experimental exploration. This significantly reduces the time and resources required for discovering these materials through traditional experimental methods.

To validate the effectiveness of their ductility test, Gaoyuan Ouyang, a scientist at Ames Lab, led the team’s experimental efforts. They conducted validation tests on a set of predicted refractory multi-principal-element alloys (RMPEAs), which have potential applications in high-temperature environments such as aerospace propulsion systems, nuclear reactors, turbines, and other energy applications.

Through their validation testing, the team observed that “the predicted ductile metals underwent significant deformation under high stress, while the brittle metal cracked under similar loads, confirming the robustness of the new quantum mechanical method,” according to Ouyang.

Their groundbreaking findings have been published in the paper titled “A ductility metric for refractory-based multi-principal-element alloys” in Acta Materialia.