Exciting Breakthrough: Grinding Could Destroy Dangerous “Forever Chemicals” in Soil

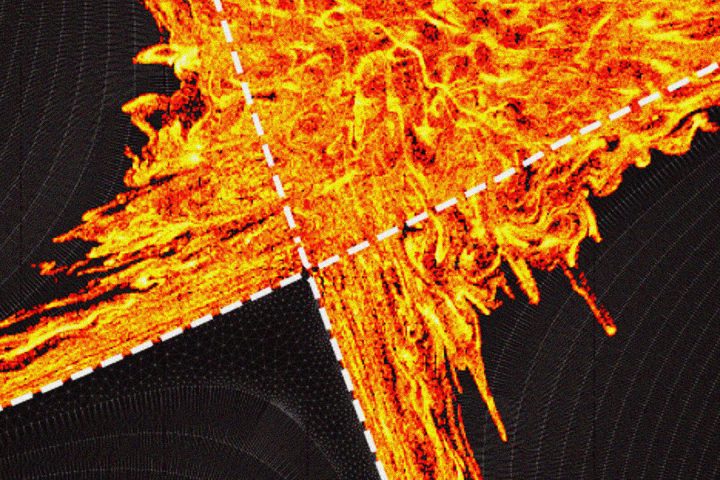

Researchers from the University of Auckland and the U.S. Environmental Protection Agency have discovered a potential solution to eliminate dangerous “forever chemicals” from soil. The team conducted a proof-of-concept study and found that grinding, specifically through a process called “ball milling,” could effectively decontaminate soil polluted by firefighting foam. This breakthrough could have significant implications for military bases, airports, and refineries worldwide that have been grappling with the presence of these harmful chemicals for decades.

Known as PFAS (per- and polyfluoroalkyl substances), these contaminants pose serious health risks, including cancer, reduced fertility, and liver damage. The U.S. Department of Defense estimates that the clean-up of contaminated sites could cost a staggering $31 billion. However, the researchers’ ball milling technique achieved a remarkable success rate of 99.88 percent to 100 percent in destroying PFAS in soil and firefighting foam.

Dr. Kapish Gobindlal, the chief scientist for Environmental Decontamination (NZ) Limited (EDL) and an honorary academic at the University of Auckland, explained that the intense grinding process using metal balls resulted in a safe by-product. The findings of this study, published in the academic journal Environmental Science: Advances, demonstrate the scalability and cost-effectiveness of this method compared to other alternatives.

“Ball milling” has the potential to revolutionize the remediation of contaminated sites, addressing the urgent need for environmental clean-up. Professor Jon Sperry, one of the researchers involved, emphasized the importance of green chemistry in solving global challenges. He stated, “This is an example of green chemistry that can help communities, the environment, and, in fact, the world.”

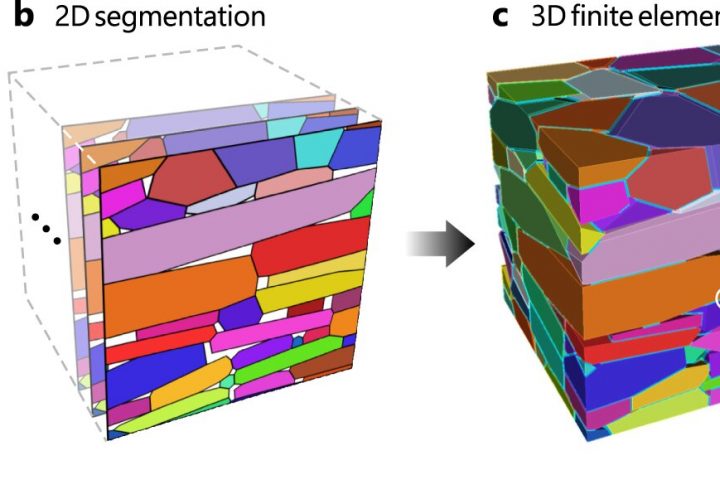

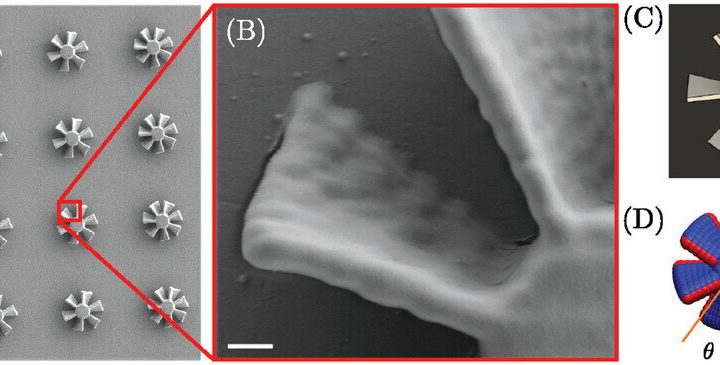

Forever chemicals like PFAS are pervasive and resistant to degradation. They can be found in various everyday products, from non-stick pans to food packaging and clothing. Firefighters have used firefighting foam containing PFAS to combat flammable liquid fires, leading to widespread contamination. The ball milling process mimics the grinding of a mortar and pestle but at an incredibly high intensity, breaking down PFAS at a molecular level.

One crucial aspect of scaling up this method is cost. The researchers used affordable and easily accessible quartz sand as part of the treatment for firefighting foam, eliminating the need for expensive additives. Laboratory experiments conducted at the University of Auckland demonstrated the effectiveness of the ball milling process in destroying PFAS in soil, firefighting foam, and activated carbon used for water treatment.

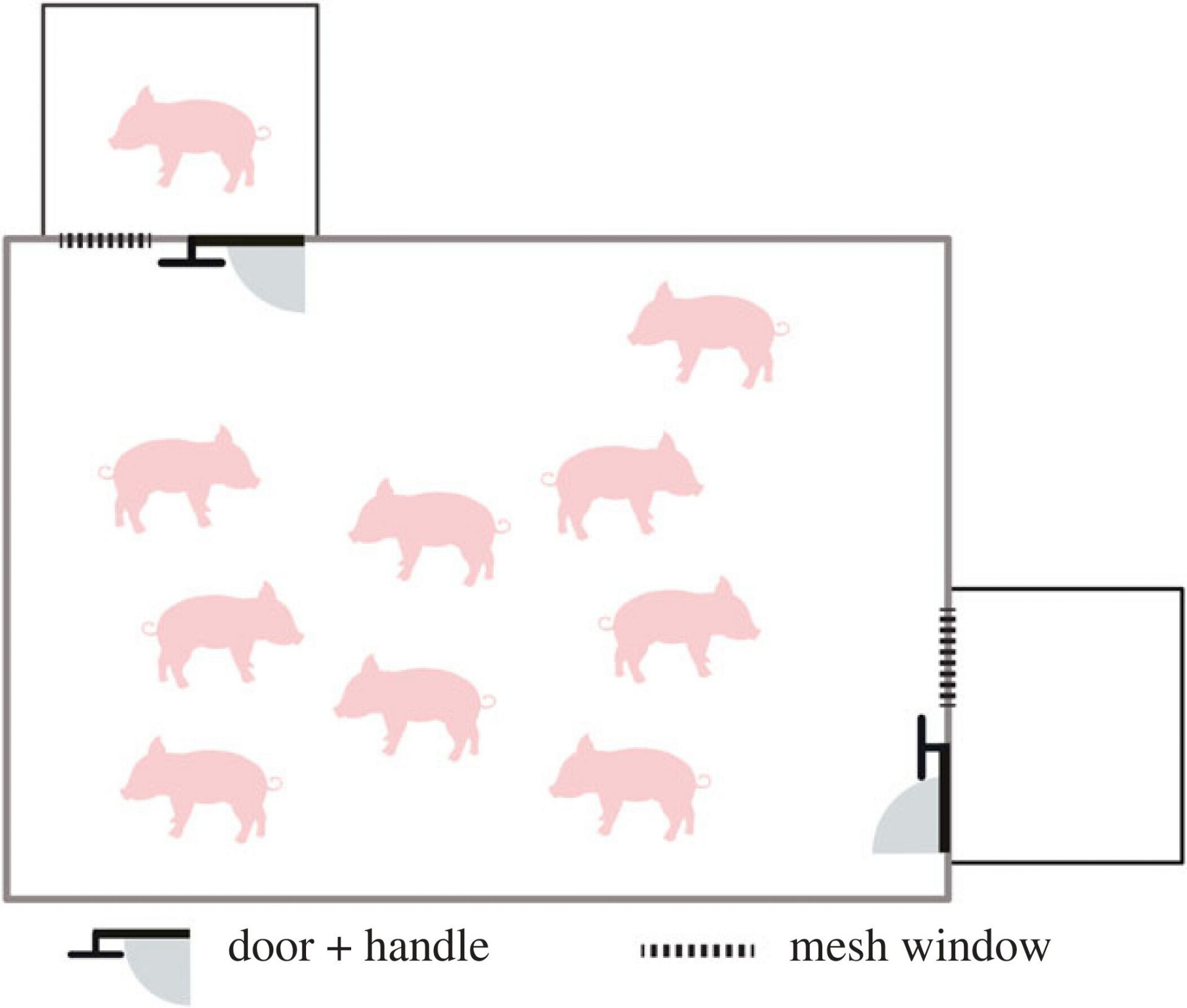

EDL’s research and development facility in Auckland is equipped with Mechanochemical Destruction (MCD) reactors housed in modified shipping containers. These reactors have the potential to treat several tons of contaminated soil per hour, offering a rapid and scalable solution.

The presence of PFAS in New Zealand has been a concern, with contamination found at various sites, including military bases and airports. The country’s Environmental Protection Agency has proposed a ban on PFAS in cosmetics, highlighting the need for comprehensive action. The global impact of PFAS pollution is evident, with significant settlements and numerous contaminated sites reported in the U.S. and Europe.

While there is still much work to be done, the discovery of the ball milling technique brings hope for a more sustainable and efficient approach to tackling the PFAS contamination crisis. With further research and investment, this method could play a vital role in safeguarding our environment and public health.