Rutgers University scientists have made a groundbreaking discovery in the field of medical coatings. Their innovative method allows for the creation of highly accurate coatings of biologically active materials, opening up new possibilities for transdermal medication. This could potentially revolutionize the way we administer vaccinations, eliminating the need for painful shots.

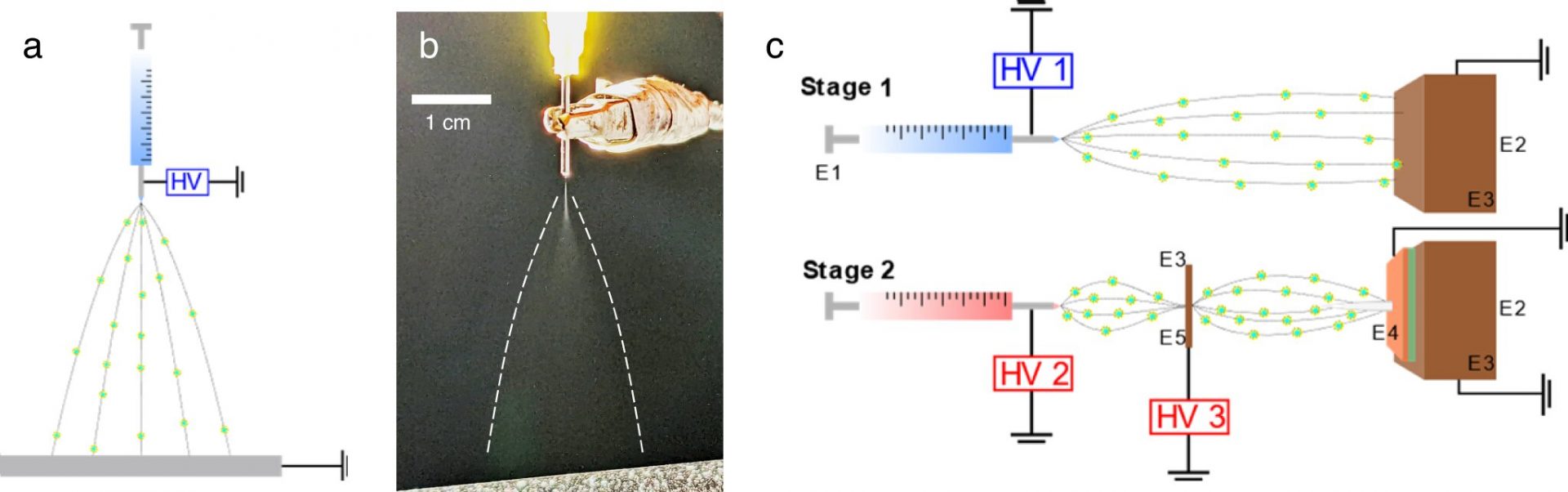

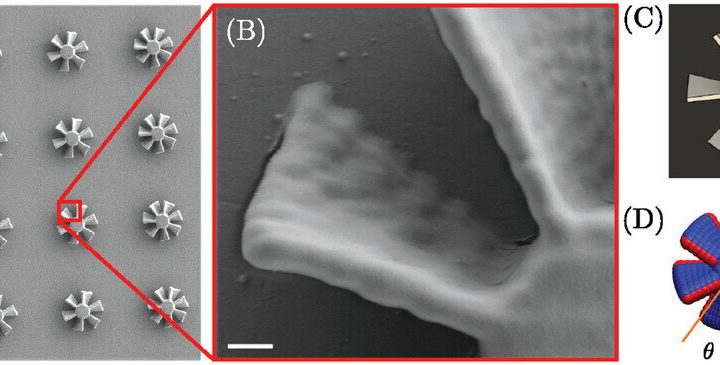

Writing in Nature Communications, the researchers described a revolutionary approach to electrospray deposition, an industrial spray-coating process. By improving control over the target region and the electrical properties of the particles being deposited, the team has significantly increased the accuracy of the spray. This means that more of the spray is now hitting its microscopic target.

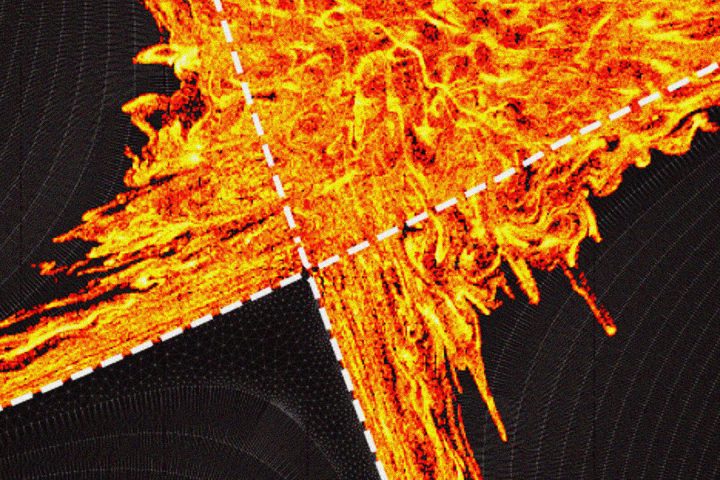

In electrospray deposition, a high voltage is applied to a flowing liquid, transforming it into fine particles. These particles then evaporate as they travel to a target area, leaving behind a solid precipitate. However, traditional methods of electrospray deposition are not efficient for targets smaller than the spray, such as the microneedle arrays in transdermal patches. The team at Rutgers University has overcome this limitation through advanced engineering techniques, achieving efficiencies that are statistically indistinguishable from 100%.

Coatings play a crucial role in various medical applications, from implanted devices like stents and pacemakers to new products utilizing biologicals like transdermal patches. However, the production of advanced bioactive materials can be expensive, especially if there is any wastage. The researchers at Rutgers University sought to determine if electrospray deposition could be an efficient method for creating biomedically active coatings. Their findings have shown that higher efficiencies in this process could revolutionize the manufacture of medical devices using bioactive materials.

“Being able to deposit with 100% efficiency means none of the material would be wasted, allowing devices or vaccines to be coated in this way,” said Sarah Park, a doctoral student involved in the study. “We anticipate that future work will expand the range of compatible materials and the material delivery rate of this high‐efficiency approach.”

Unlike other coating techniques used in manufacturing, such as dip coating and inkjet printing, the new electrospray deposition technique is characterized as “far field.” This means that it doesn’t require highly accurate positioning of the spray source, making the equipment necessary for mass manufacturing more affordable and easier to design.

The team of scientists at Rutgers University includes experts from various departments, all working together to push the boundaries of medical coatings. Their groundbreaking research has the potential to transform the field and improve the efficiency of medical treatments.