Glass fiber-reinforced plastic (GFRP) is a versatile and durable material used in a wide range of applications, from aircraft parts to windmill blades. However, its strength and durability also make it challenging to dispose of, leading to most GFRP waste being buried in landfills.

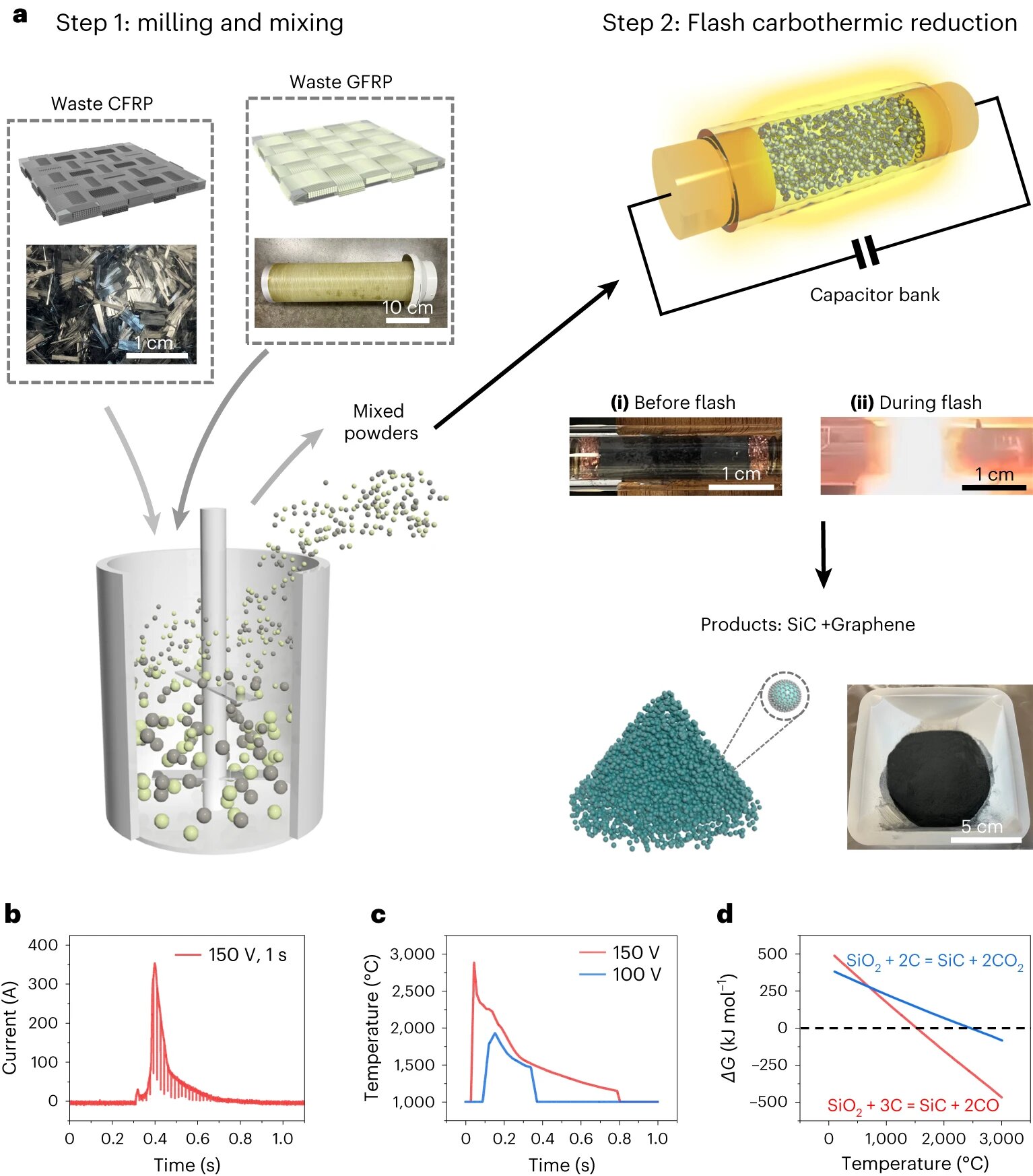

But now, researchers at Rice University have developed an innovative upcycling method to transform GFRP into silicon carbide, a valuable material used in semiconductors and other products. This new process is energy-efficient and environmentally friendly, offering a sustainable solution to the growing issue of GFRP waste disposal.

By utilizing flash Joule heating, the researchers are able to convert GFRP into silicon carbide at high temperatures, opening up new possibilities for recycling and repurposing this waste material. With operating costs lower than traditional disposal methods, this upcycling process has the potential to revolutionize how we handle GFRP waste and contribute to a more circular economy.

Join us in supporting this groundbreaking research and help turn GFRP trash into treasure for a brighter, more sustainable future.