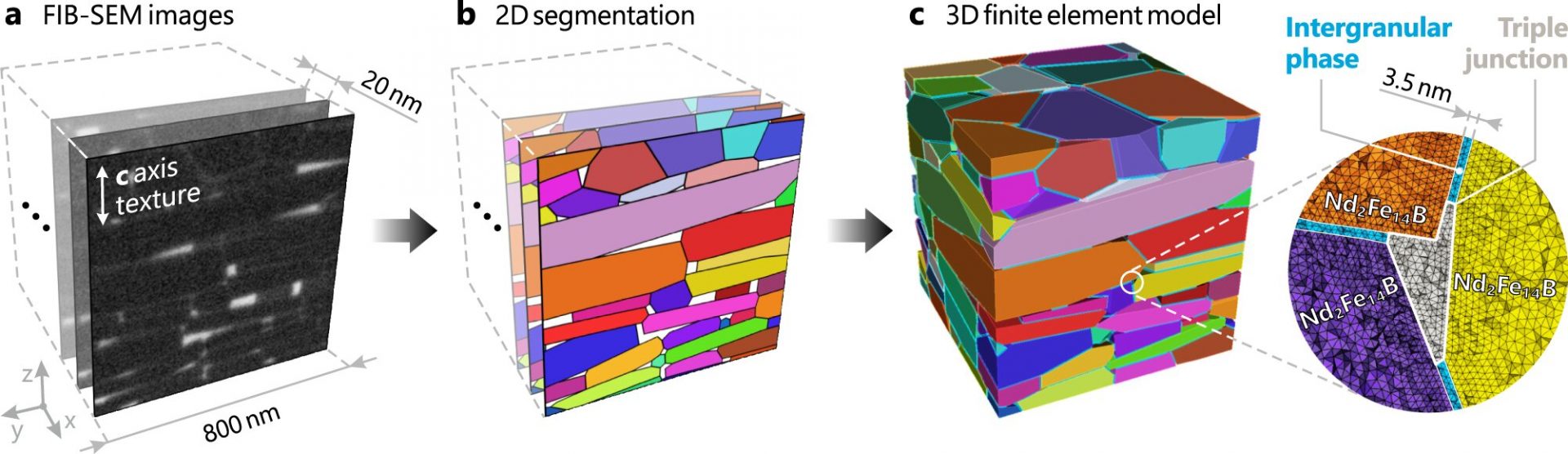

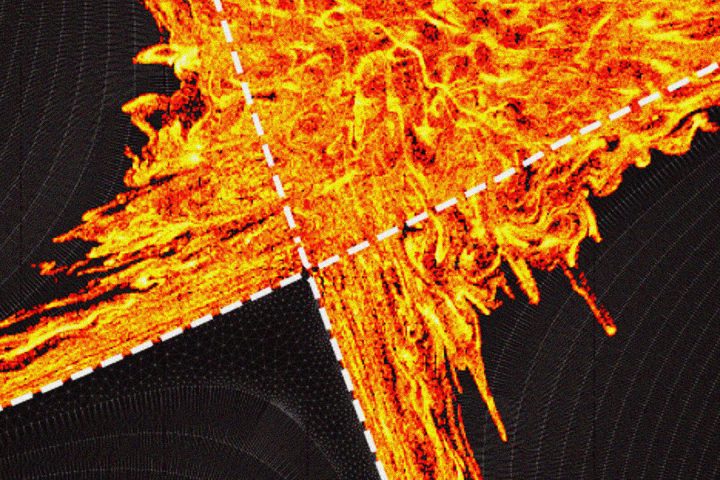

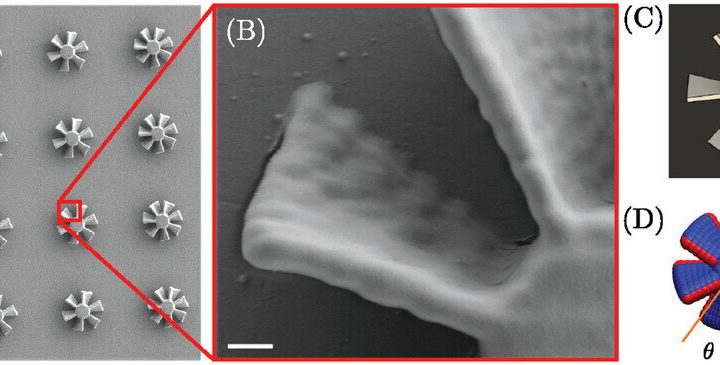

NIMS has achieved a breakthrough in simulating the magnetization reversal of Nd-Fe-B magnets using cutting-edge large-scale finite element models based on tomographic data from electron microscopy. These simulations have uncovered crucial microstructural details that impact coercivity, the measure of a magnet’s ability to resist demagnetization in the face of opposing magnetic fields. By leveraging new tomography-based models, we are paving the way towards the creation of sustainable permanent magnets with unparalleled performance. Industries such as green energy production, electric transportation, and high-tech sectors heavily rely on high-performance permanent magnets, with Nd-Fe-B magnets being the most powerful and sought after. However, the coercivity of industrial Nd-Fe-B magnets has yet to reach its full potential. To address this challenge, micromagnetic simulations on realistic magnet models are essential. Our research introduces a novel method to reconstruct the true microstructure of ultrafine-grained Nd-Fe-B magnets in large-scale models, as detailed in our recent publication in the journal npj Computational Materials. By utilizing tomographic data from SEM images and FIB polishing, we can create high-quality 3D finite element models. This tomography-based approach is versatile and can be applied to various polycrystalline materials, offering solutions to a wide array of materials science issues. Micromagnetic simulations on these tomography-based models have successfully replicated the coercivity of ultrafine-grained Nd-Fe-B magnets and elucidated its underlying mechanisms. The microstructural characteristics influencing coercivity and magnetization reversal nucleation have been unveiled. Consequently, the developed model serves as a digital twin of Nd-Fe-B magnets, accurately reflecting their physical properties. These digital twins can precisely replicate both the microstructure and magnetic attributes, enabling their use in designing high-performance permanent magnets tailored to specific applications. By inputting the desired magnetic properties for a particular use case, such as traction or variable magnetic force motors, researchers can leverage a data-driven research pipeline with integrated digital twins to recommend the optimal magnet composition, processing parameters, and microstructure, significantly reducing development timelines.

Scientists simulate magnetization reversal of Nd-Fe-B magnets using large-scale finite element models