The antibiotic cefazolin is a game-changer in global healthcare. Recognized as an essential drug by the World Health Organization (WHO), it has traditionally been produced through batch manufacturing. However, groundbreaking research has now introduced a more efficient and cost-effective method: continuous-flow manufacturing. This innovative approach allows for faster production, reduced waste, and greater flexibility in meeting demand.

Improving access to cefazolin is crucial for global health, especially in countries like Japan that faced shortages in 2019. The findings of this study have been published in the esteemed Bulletin of the Chemical Society of Japan.

Antibiotics are our frontline defense against serious bacterial infections, and the demand for them continues to rise. Cefazolin, in particular, is a vital medication designated as essential by the WHO. It effectively treats a wide range of ailments, including urinary tract, respiratory, and joint infections, as well as preventing post-surgical infections.

Traditionally, cefazolin has been manufactured using batch manufacturing, a meticulous process that ensures precise control at each stage. However, this method is time-consuming, requires extensive space, and generates significant waste, making it expensive and challenging to establish new facilities.

Enter continuous-flow manufacturing, an alternative approach that offers numerous advantages. While drugmakers have been hesitant to adopt this method due to the complexities of controlling reactions, researchers at the University of Tokyo have successfully developed a safe and efficient way to produce cefazolin through continuous-flow manufacturing.

“Our method allows for mass production within compact facilities, eliminating the need for costly equipment while ensuring the production of pharmaceutical-grade cefazolin,” explained Professor Shu Kobayashi from the Department of Chemistry at the Graduate School of Science.

“The demand for this antibiotic can fluctuate significantly, and it’s best not to prepare it too far in advance due to its instability,” added Project Professor Haruro Ishitani, also from the Department of Chemistry. “The continuous-flow method offers the advantage of easily adjusting the production volume as needed.”

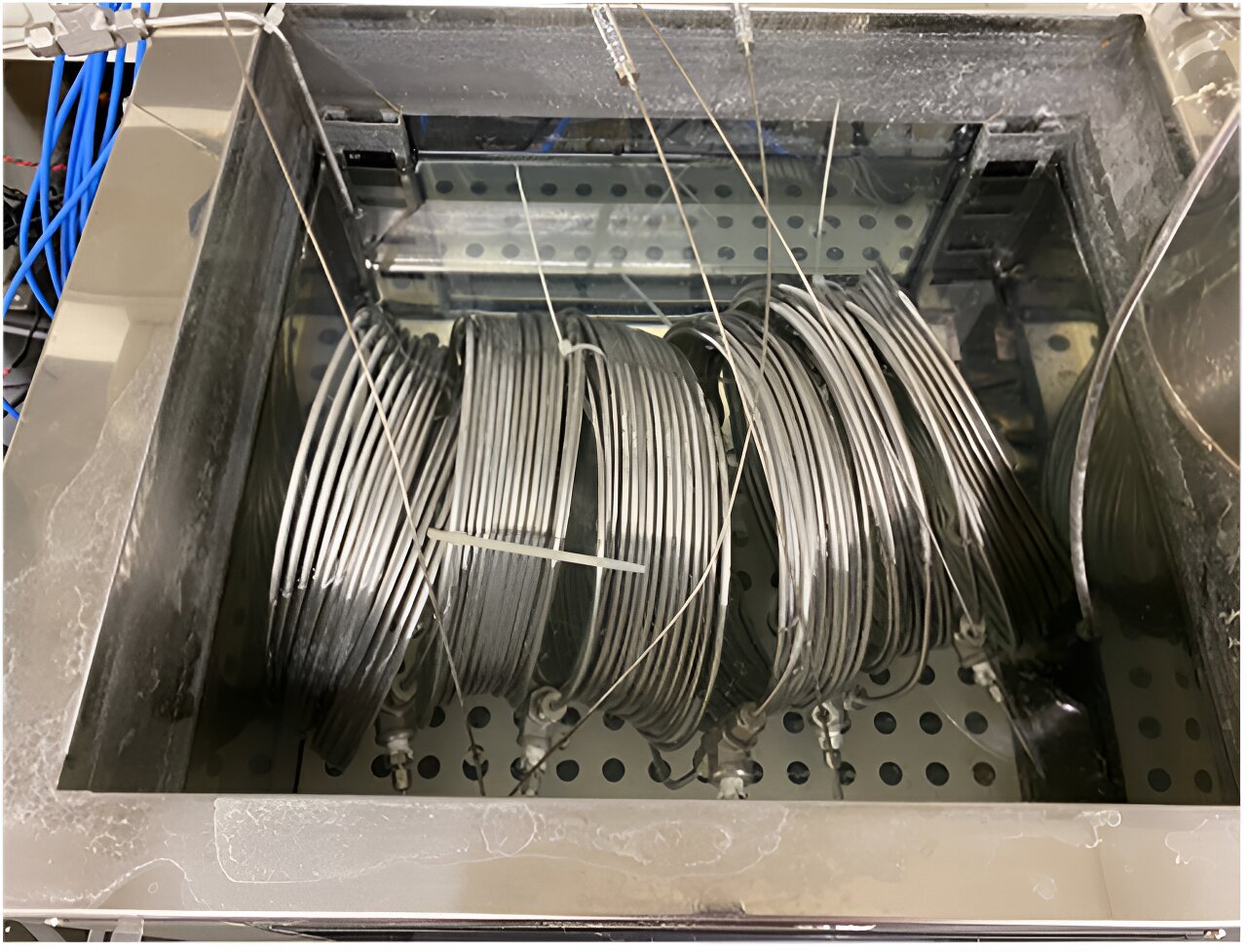

Unlike the batch method, continuous-flow manufacturing operates without pauses between individual steps. The research team utilized two interconnected reactors to produce cefazolin using readily available commercial raw materials. By optimizing the environment inside the reactors, including temperature, transfer speed, and mixing ratio of reagents, they achieved a high-purity product, surpassing the capabilities of conventional batch manufacturing.

Professors Kobayashi and Ishitani were driven by Japan’s reliance on imported drugs like cefazolin, leading to shortages in critical situations. The continuous-flow method not only offers a more accessible and cost-effective solution on a national scale but also empowers smaller communities and hospitals to manufacture essential drugs as needed.

“Continuous-flow methods have the potential to synthesize many compounds,” said Professor Ishitani. “By adopting this approach, we can ensure a stable drug supply, address rare diseases and disasters, facilitate new drug development, and even contribute to other chemical production, such as for agricultural use and the realization of a low-carbon society.”