Chemical structures called cyclopropanes have the power to enhance the effectiveness and fine-tune the properties of many drugs. However, the traditional methods used to create these structures are limited to certain molecules and involve highly reactive and potentially explosive ingredients.

Now, a team of researchers from Penn State has discovered a safe, efficient, and practical method to create cyclopropanes on a wide range of molecules using a previously unknown chemical process. This groundbreaking method, described in a paper publishing on Aug. 4 in the journal Science, has the potential to revolutionize drug development and production.

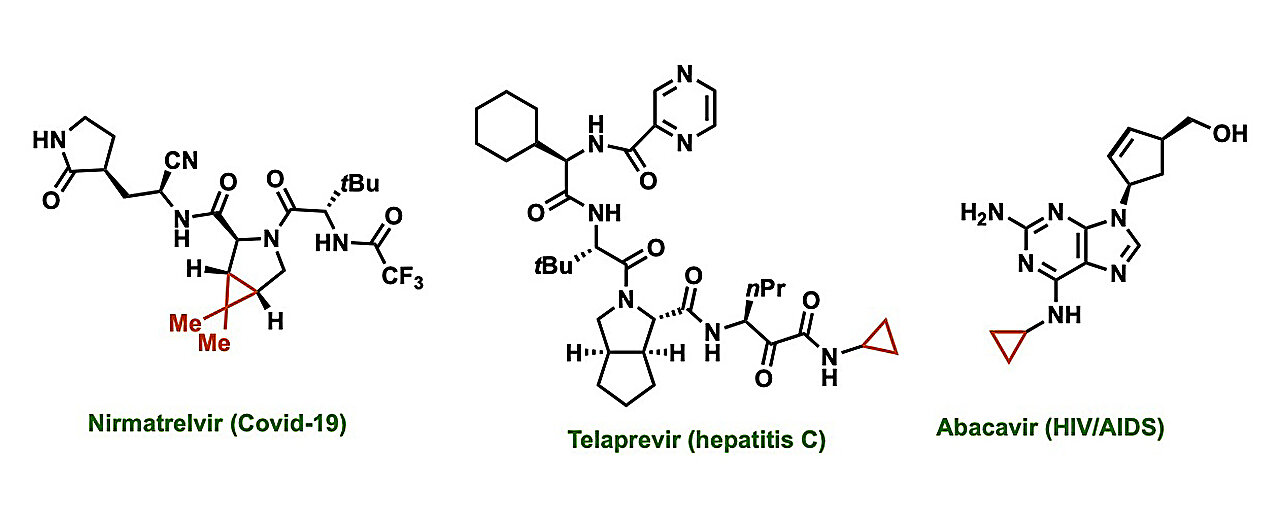

Cyclopropanes play a crucial role in many FDA-approved drugs, including those used to treat COVID-19, asthma, hepatitis C, and HIV/AIDS. These structures can enhance a drug’s potency, control its solubility in the body, minimize unintended interactions, and optimize performance. Cyclopropanes consist of a ring of three carbon atoms, with one carbon attached to the rest of the drug molecule and the other two each attached to two hydrogen atoms.

“Cyclopropanes are essential in many drugs, and incorporating them into drug candidates is a critical part of the drug discovery process,” explained Ramesh Giri, professor of chemistry at Penn State and leader of the research team. “Previous efforts to improve cyclopropane synthesis focused on modifying an established mechanistic pathway from over 60 years ago. We took a different approach and identified a completely new pathway that is simple, practical, and widely applicable.”

The new method transforms a specific chemical structure, called alkenes, into cyclopropanes. Alkenes are commonly used in the synthesis of various molecules. The method harnesses the power of “radical chemistry,” where intermediate steps of reactions generate free radicals—carbon atoms with unpaired electrons—that drive the reaction forward. This innovative method utilizes visible light to initiate the reaction and employs readily available chemical ingredients, including oxygen.

Unlike traditional methods, which require highly reactive and hard-to-obtain ingredients and must be conducted under controlled conditions, the new method bypasses the need for a highly reactive intermediate compound called a carbene. Instead, it produces the necessary unpaired electrons one at a time as radicals. The ingredients used in this method are commercially available, easy to handle, and do not require special safety precautions. The resulting product can be stored for extended periods.

“We can combine all the ingredients in one mixture, exposed to air with as little as 10% oxygen, and the reaction proceeds in a single step. It is a simple and safe process, to the extent that we are considering including it in undergraduate chemistry labs,” said Giri.

Another limitation of traditional methods is their inability to work with complex molecules. Cyclopropanes are typically introduced early in the synthesis process when the molecule is less complex. However, subsequent steps can cause the ring to open up, requiring a backtrack to the early stages for further modifications.

Using the new method, the researchers successfully converted a variety of alkenes, including pharmaceutically relevant compounds like estrone, penicillin, and vitamin B, into cyclopropanes, regardless of their complexity.

“We explored the entire range of molecule complexity encountered in drug synthesis. While traditional methods may achieve the same end product, they often require more steps. In some cases, traditional methods are unable to create these products due to the sensitivity or complexity of the starting alkenes. Our new method is not only safer, more efficient, and practical, but also has a wider range of applications,” Giri explained.

The reaction’s ingredients can be modified to add different chemical groups to the final product, allowing for various therapeutic goals. One of the ingredients, a compound called a methylene, can be substituted with hundreds of commercially available methylenes, each with unique chemical groups that can be incorporated into the cyclopropane. The researchers demonstrated the versatility of the new method using 19 different methylene compounds.

“At first, the idea of using visible light and radical chemistry to transform alkenes into cyclopropanes using methylenes may seem counterintuitive. That’s why it was crucial for us to thoroughly demonstrate this new catalytic method,” said Giri. “The key insight was introducing oxygen into the reaction, which helps create a radical that interacts with the alkene. My lab has been studying other reactions involving alkenes and radicals, and we wondered if the same concept could be applied to cyclopropane synthesis.”

Next, Giri and his team plan to scale up the method for industrial use.

“With further development and scaling, this method has the potential to revolutionize cyclopropane synthesis, which would have significant implications for drug discovery, development, and production,” he concluded.

In addition to Giri, the research team at Penn State includes postdoctoral researchers Dhruba Poudel, Amrit Pokhrel, Raj Kumar Tak, and Majji Shankar.