A groundbreaking invention has emerged from a collaboration between researchers in Singapore and the UK. Led by Dr. Wei Liang Lai, with the guidance of Associate Professor Kheng Lim Goh, the team has developed a portable device capable of repairing hard-to-detect damage in carbon fiber materials. This device holds immense potential for the aerospace industry, particularly in the repair of commercial aircraft fuselages. Their remarkable work has been published in the esteemed journal Polymers for Advanced Technologies.

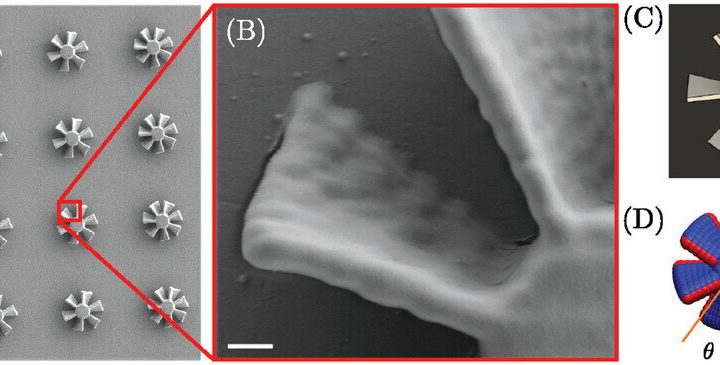

A revolutionary handheld device has been created to address nearly invisible damage on carbon fiber and epoxy materials. The researchers conducted tests on materials with varying layer counts, specifically 16 and 24 layers. They also experimented with three different types of adhesives: regular epoxy, epoxy mixed with halloysite nanotubes (E1HNT), and epoxy mixed with carbon nanotubes (NF100, also known as “NanoForce E100” from Nano-Tech SPA). Infrared technology and compression testing were utilized to assess the effectiveness of the repairs.

Regrettably, the damaged materials proved to be significantly weaker than their undamaged counterparts. The researchers discovered that the number of layers in the material played a crucial role in determining the success of the repairs. For the 16-layer material, using regular epoxy or E1HNT in a vacuum yielded the best results in terms of restoring its stretchy properties. On the other hand, using E1HNT adhesive at regular atmospheric pressure proved most effective in fixing fractures.

However, the repairs on the 24-layer material fell short of fully restoring its original strength due to the complexity of the damage. The researchers engaged in a discussion regarding the most effective repair methods for restoring specific properties of the materials.

Prior to this study, the researchers had already examined the properties of various resin types to determine the most suitable ones for repairing damaged composite materials. They explored the potential of halloysite nanotubes (HNT) and carbon nanotubes (CNT) as additives to enhance the adhesive properties for repairing damaged materials. However, they needed to evaluate the performance of these particle-adhesive blends, taking into account factors such as preparation methods, the effects of different particle types, and the appropriate quantities to be added.

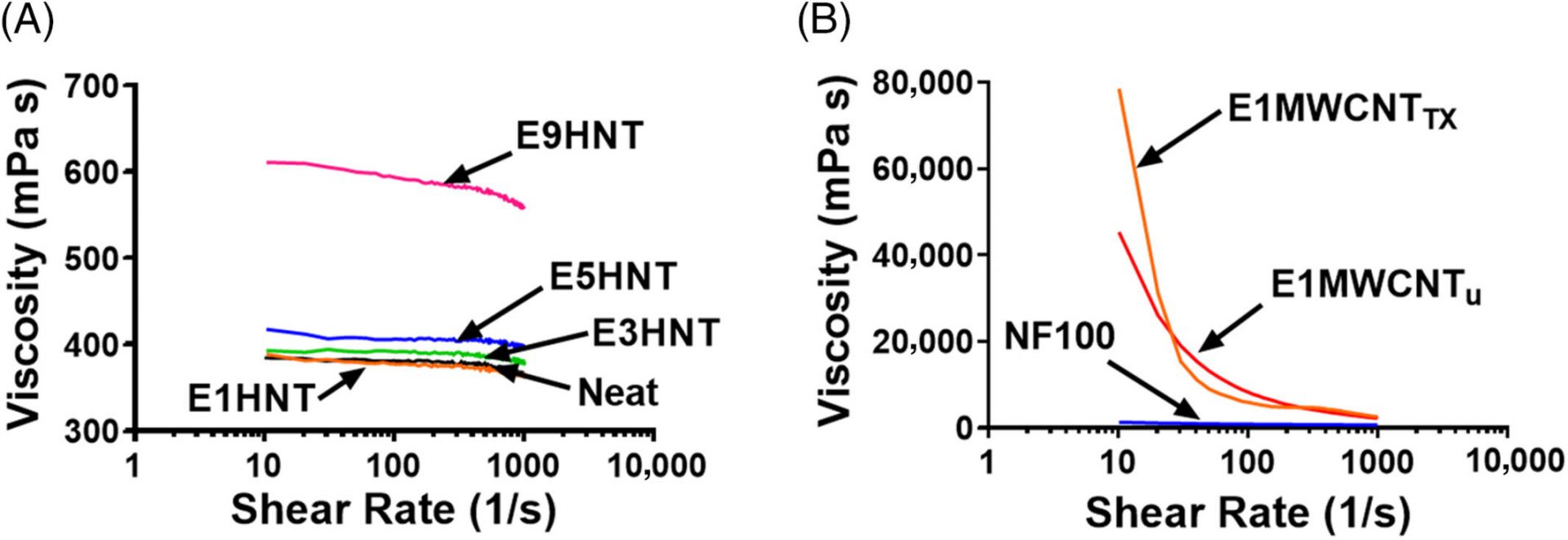

Two commercially available adhesives, Epo-Tek 301 and NanoForce E100, were studied, along with mixtures of Epo-Tek 301 combined with varying amounts of HNTs, and Epo-Tek 301 combined with treated and untreated CNTs.

The researchers examined multiple properties of these adhesives, including strength (using a specialized micromechanical tester developed jointly by researchers from Sensorcraft Technology (S) Pte Ltd and Newcastle University in Singapore), adhesion capabilities, physical traits such as spreadability, heat resistance, and chemical characteristics.

The results revealed that adding 1% of HNTs to Epo-Tek 301 had minimal impact on its properties, but higher concentrations weakened the adhesive and altered its behavior when exposed to heat. Conversely, the addition of CNTs did not improve the adhesive’s properties. In fact, adhesives with CNTs became thicker and may not be suitable for effectively repairing composite materials, as they may struggle to penetrate damaged areas.

Therefore, when selecting an adhesive for repairing damaged composite materials, it is crucial to make a wise choice, taking into consideration all of these factors.