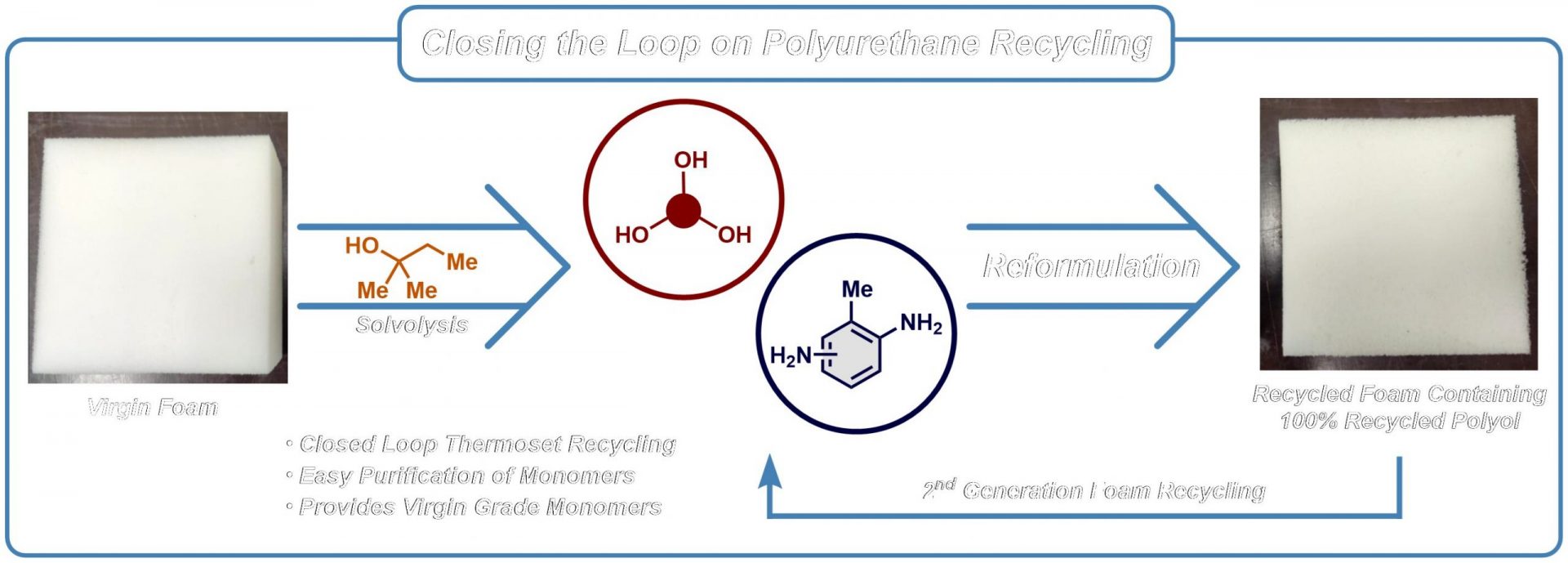

Back in 2022, researchers from Aarhus University made waves with their groundbreaking discovery. They found a cost-effective way to break down polyurethane (PU) plastic into its original components, allowing for recycling into new PU material instead of ending up in landfills or incinerators.

Now, in collaboration with Plixxent A/S, Dan-Foam Aps, and the Danish Technological Institute as part of the Danish RePURpose consortium, these researchers have taken their method a step further. They have successfully applied it to tackle flexible foam polyurethane.

By breaking down approximately 1.5 kilos of foam mattress and extracting its main components, they were able to use polyol, one of the extracted materials, as a raw material in a new mattress. Remarkably, they replaced 64% of the mattress with recycled polyol, without compromising its quality.

What’s more, they have demonstrated that this process can be repeated multiple times. The polyol can be re-extracted from polyurethane foam and reused again.

Their groundbreaking results have just been published in the prestigious journal ACS Sustainable Chem & Engineering.

A Solution in High Demand

This breakthrough takes us one step closer to achieving a circular economy for flexible PU foam, which is desperately needed. Currently, the majority of global PU waste ends up in landfills due to the challenges of recycling. Unlike many other plastics, PU cannot be melted and molded into new products.

In 2021, the global market for PU reached a staggering 24.7 million tons, and it is projected to exceed 29 million tons by 2029. Flexible PU foam, commonly used in mattresses, accounts for approximately 30% of this market.

PU is not limited to mattresses; it is a versatile group of advanced plastic materials with countless applications. It is used in furniture, refrigerators, shoes, toys, paints, insulation, cars, wind turbines, aircraft, and much more.

Challenges Ahead

The method developed and patented by the chemists at Aarhus University is called solvolysis. It involves breaking down the chemical bonds in PU by subjecting the material to hot tert-amyl alcohol and a small amount of caustic potash in a specialized pressure cooker.

However, the researchers acknowledge that this process may not be suitable for the entire PU market due to the diverse nature of PU materials.

“Our technique can pave the way for a circular economy for PU mattresses. However, for recycling to truly replace landfilling and incineration, we need comprehensive waste management. The challenge lies in the fact that each manufacturer of PU-based materials has their own unique recipe,” explains Assistant Professor Steffan Kvist Kristensen from the Interdisciplinary Nanoscience Center (iNANO) at Aarhus University, who co-authored the study.