A groundbreaking study conducted by researchers from the University of Chemistry and Technology in Prague has unveiled the fascinating properties and performance of dry-coated paracetamol particles. In this study, carnauba wax was utilized as the coating agent, and the findings, published in the esteemed Journal of Pharmaceutical Analysis, have provided invaluable insights into the thickness, homogeneity, and dissolution characteristics of these coated particles.

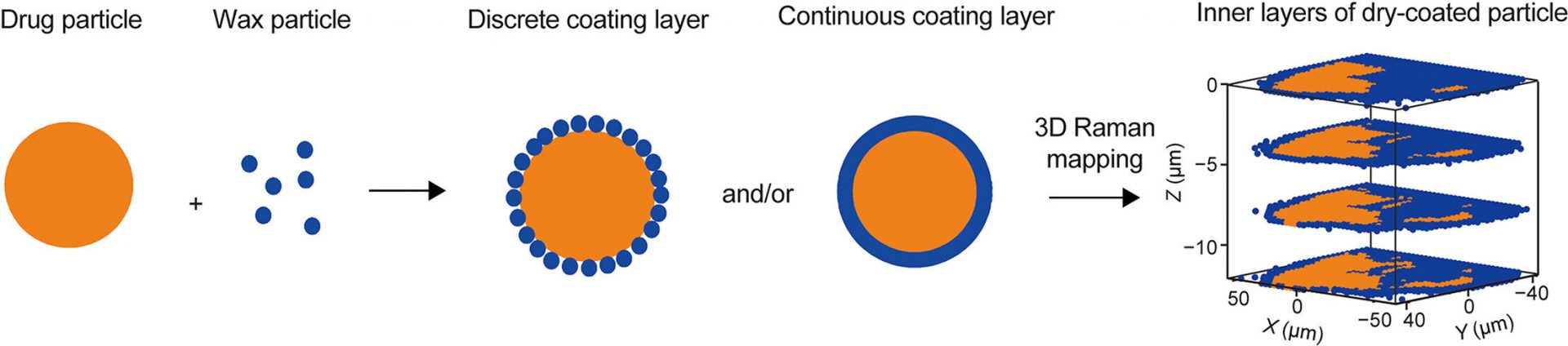

The research focused on the utilization of carnauba wax as a dissolution retardant to enhance the drug delivery properties of paracetamol. By employing non-destructive Raman mapping techniques, the scientists were able to examine the coated particles without altering their structure. This innovative application of Raman mapping techniques revealed the presence of two distinct forms of wax on the surface of paracetamol particles, forming a porous coating layer.

The first form involved intact wax particles residing on the surface of paracetamol, adhering to other wax particles present. The second form consisted of deformed wax particles spread across the surface. This unique coating structure provided a porous layer, offering promising potential for controlled drug release.

Remarkably, the study found that the coating thickness exhibited significant variability in the range of a few microns, regardless of the final particle size fraction. This finding highlights the necessity for precise analytical methods to characterize the coating thickness in pharmaceutical products, ensuring optimal drug release profiles.

Furthermore, the researchers confirmed the ability of carnauba wax to effectively decrease the dissolution rate of paracetamol through experiments with powder and tablet formulations. The dissolution rate was observed to be slower for larger coated particles, demonstrating the influence of particle size on drug release kinetics.

Importantly, the study emphasized the critical role of subsequent formulation processes, such as tableting, in further reducing the dissolution rate. These findings underscore the significant impact of formulation techniques on the final quality and performance of pharmaceutical products.

Dr. Georgia Koutentaki commented on the implications of the research, stating, “Our investigation highlights the potential of carnauba wax as a valuable coating agent for enhancing the performance of fast-dissolving drugs like paracetamol. By understanding the coating structure and its impact on dissolution rates, we can optimize drug delivery systems and develop more effective pharmaceutical formulations.”

The findings of this research hold considerable promise for the pharmaceutical industry, providing a deeper understanding of dry-coated paracetamol particles and their potential applications for controlled drug release. The development of improved drug delivery systems has the potential to enhance patient experiences and optimize therapeutic outcomes.

,,,