A team of brilliant researchers from Virginia Tech has made an incredible breakthrough in the world of plastics. They have developed a groundbreaking method for transforming plastics into valuable chemicals called surfactants, which are used in the production of soap, detergent, and more. This groundbreaking work has been published in the prestigious journal Science.

Plastics and soaps may seem worlds apart, but on a molecular level, they share surprising similarities. Polyethylene, one of the most commonly used plastics today, has a chemical structure that closely resembles that of a fatty acid, a key ingredient in soap production. Both materials consist of long carbon chains, with fatty acids having an additional group of atoms at the end of the chain.

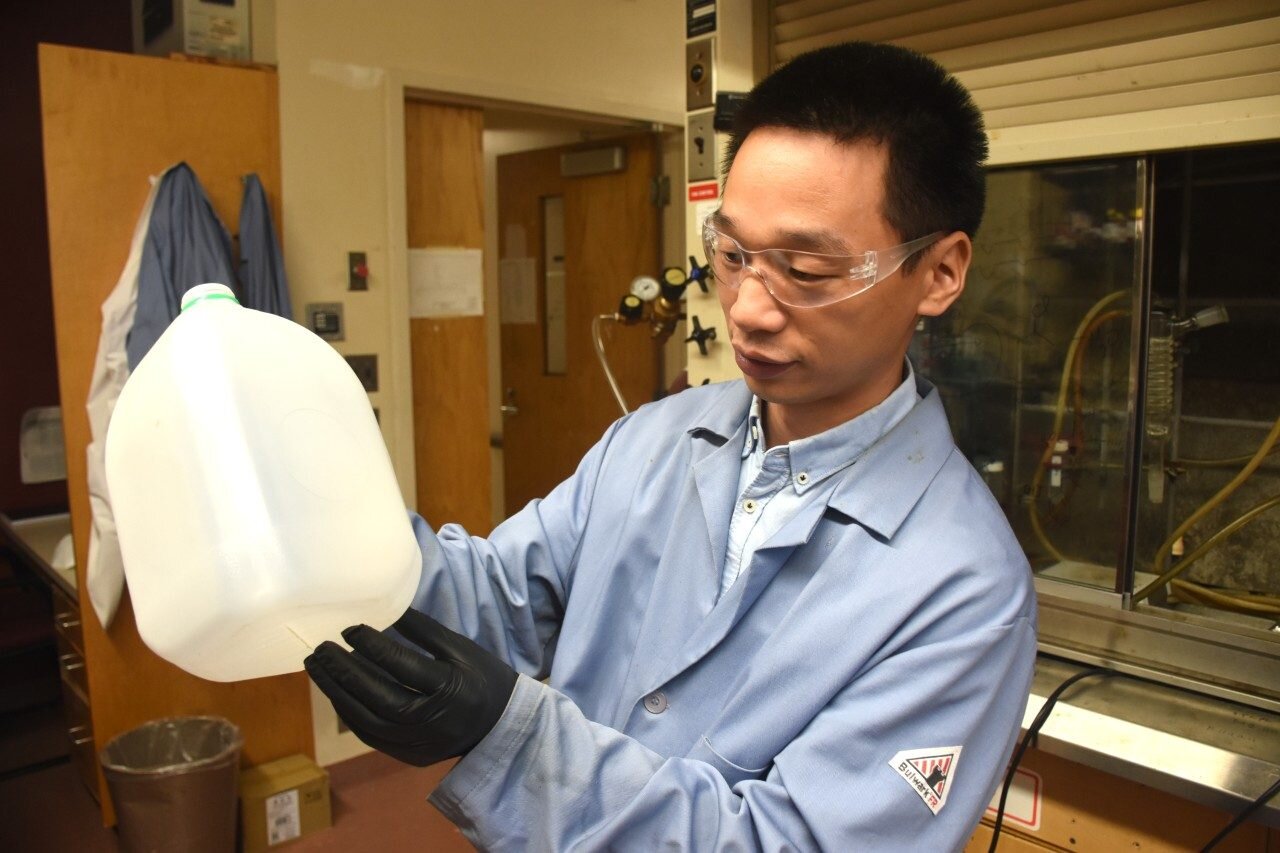

Driven by this intriguing similarity, Associate Professor Guoliang “Greg” Liu from the Virginia Tech College of Science envisioned a way to convert polyethylene into fatty acids and ultimately produce soap. The challenge was finding an efficient method to break down the long polyethylene chains into shorter, usable chains. Liu believed that this breakthrough could transform low-value plastic waste into a valuable commodity.

After much contemplation, Liu found inspiration while enjoying a cozy winter evening by a fireplace. As he watched the smoke rise from the fire, he wondered if burning polyethylene in a controlled laboratory setting could produce a similar “smoke” composed of useful molecules. This sparked the team’s journey towards discovering a new upcycling method.

With the assistance of two talented Ph.D. chemistry students, Zhen Xu and Eric Munyaneza, Liu built a specialized reactor to perform temperature-gradient thermolysis on polyethylene. This process involved heating the plastic at the bottom of the reactor to break down the polymer chains, while cooling the top to prevent further breakdown. The residue obtained from this process turned out to be “short-chain polyethylene,” or waxes, confirming Liu’s hypothesis.

This breakthrough marked the first step towards upcycling plastics into soap. By adding a few more steps, including saponification, the team successfully created the world’s first soap made from plastics. To refine the process, experts in computational modeling and economic analysis were brought on board, resulting in a comprehensive upcycling method ready to be shared with the scientific community.

What makes this method even more remarkable is its versatility. While polyethylene served as the initial inspiration, the upcycling technique can also be applied to another commonly used plastic called polypropylene. This means that both plastics can be processed simultaneously, eliminating the need for meticulous sorting. Additionally, the method’s simplicity and reliance on heat make it cost-effective and environmentally friendly.

For large-scale implementation, the final product must be valuable enough to cover the costs of the process and make it economically attractive. Surprisingly, soaps and detergents are worth double or triple the price of plastics when compared by weight. With the demand for soap and related products comparable to that of plastics, this upcycling method holds immense potential.

This groundbreaking research paves the way for a new approach to waste reduction by transforming used plastics into valuable materials. Liu envisions recycling facilities worldwide adopting this technique, leading to the production of sustainable soap products and a significant reduction in plastic waste in landfills.

As Liu emphasizes, plastic pollution is a global challenge that requires accessible solutions. This simple yet effective upcycling process can be implemented by countries worldwide, making a significant impact in the fight against plastic pollution.

The research team also included experts from the Department of Chemical Engineering, further enhancing the depth and impact of their findings.