Films made of aluminum-plastic laminates (APL) have long been used extensively to extend the shelf life of various foods, including chips, roasted and powdered coffee, milk, and fruit juices. But did you know that during the COVID-19 pandemic, they were also used to package FFP2 masks and rapid tests?

The films consist of several polymer layers and an aluminum layer, which provide protection against damaging factors such as sunlight, heat, moisture, and oxygen. However, recycling these composite films has always been a challenge due to the combination of different materials.

But now, a groundbreaking upcycling process developed in Bayreuth offers a solution to improve the recycling of APL waste and reduce global energy consumption. With cooling systems already accounting for around 15% of global energy consumption, finding sustainable alternatives is crucial, especially in the face of climate change and heat waves.

The aluminum layer in APL packaging acts as a mirror-like reflective surface, similar to emergency blankets. By applying a clear polymer layer that enhances the radiation of thermal energy, a powerful cooling system can be created. Surprisingly, a simple laminating film commonly found in office supply stores is sufficient for this purpose.

These innovative cooling foils can be applied to any surface in the open air, such as umbrellas, blinds, and awnings, effectively preventing heating from glaring sunlight. The ambient heat is then diverted to the cool space without the need for external energy supply. This remarkable effect is known as “passive daytime cooling” and can even lead to temperatures below the ambient temperature, even in intense sunlight.

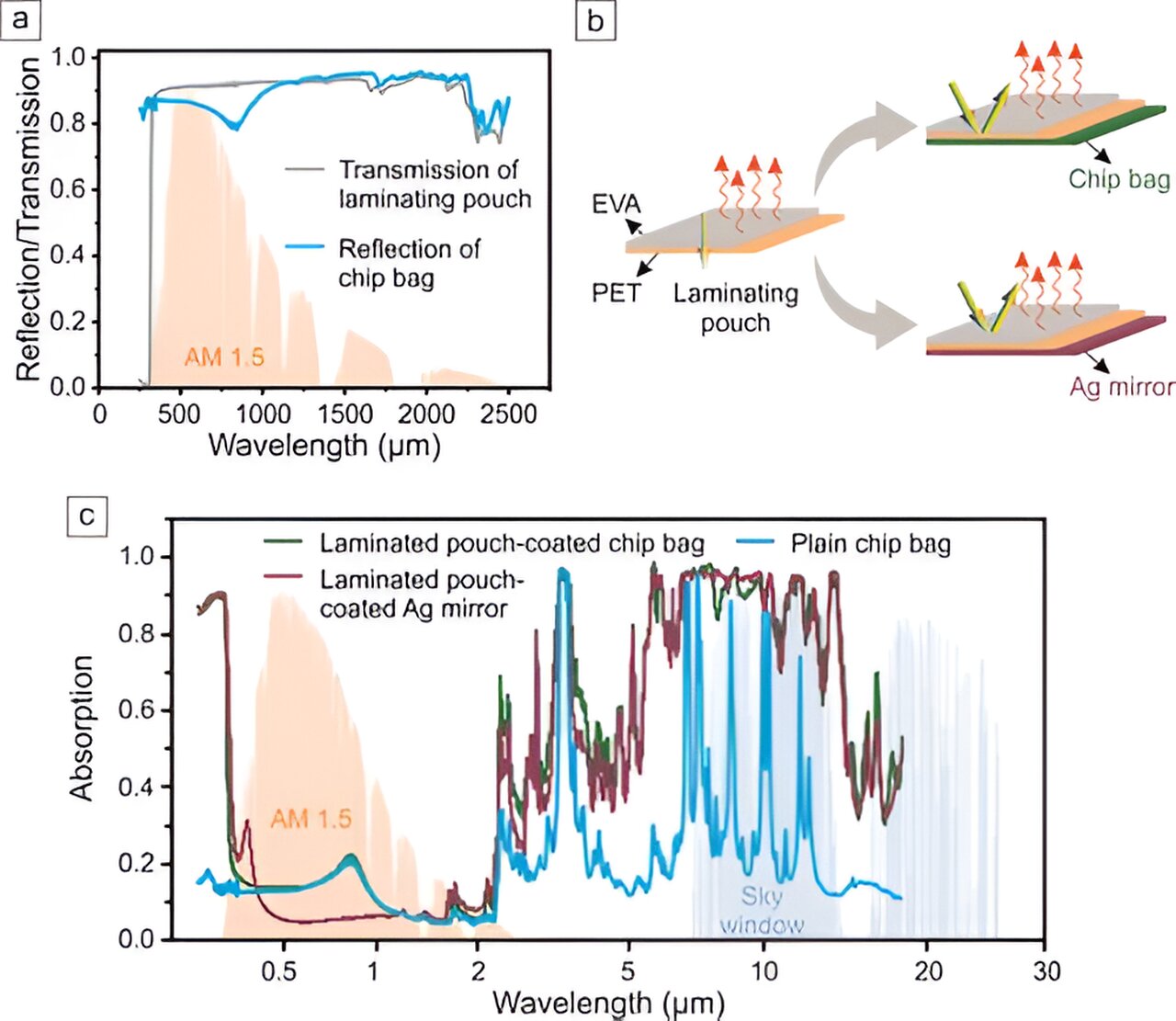

Passive daytime cooling is made possible by using materials that meet specific optical requirements. They must scatter or reflect as much sunlight as possible, which falls within the wavelength range of 0.3 to 2.5 micrometers. Additionally, in the wavelength range of 8 to 13 micrometers, known as the “sky window,” they must emit as much thermal energy as possible into space through infrared radiation.

Aluminum-plastic composite foils excel in meeting these requirements. In fact, the Bayreuth researchers found that around 87% of sunlight is reflected by the aluminum layer in coated commercial potato chips bags. The additional polymer coating of these new sustainable cooling foils enhances radiation in the sky window wavelength range, effectively emitting heat directly into space.

Prof. Dr. Markus Retsch and his colleague Dr. Qimeng Song have explored various methods of transforming potato chip bags and other APL packaging into efficient cooling materials. While industrial processes using polydimethylsiloxane (PDMS) as a coating material are possible, their recent study published in ACS Sustainable Chemistry & Engineering suggests that anyone could undertake the coating process in the future.

All you need is simple commercial laminating equipment to turn old APL packaging into cooling materials that can be used as heat shields on patios, balconies, exterior walls, or roofs.

Additional research on this topic is published in Advanced Materials Technologies.