Are you tired of the dry and astringent feel of plant-based meat alternatives? Well, scientists at the University of Leeds have found a solution to this problem. They have developed a groundbreaking technique that transforms plant proteins into juicy and fat-like substances, simply by adding water.

Introducing Plant Protein Microgels

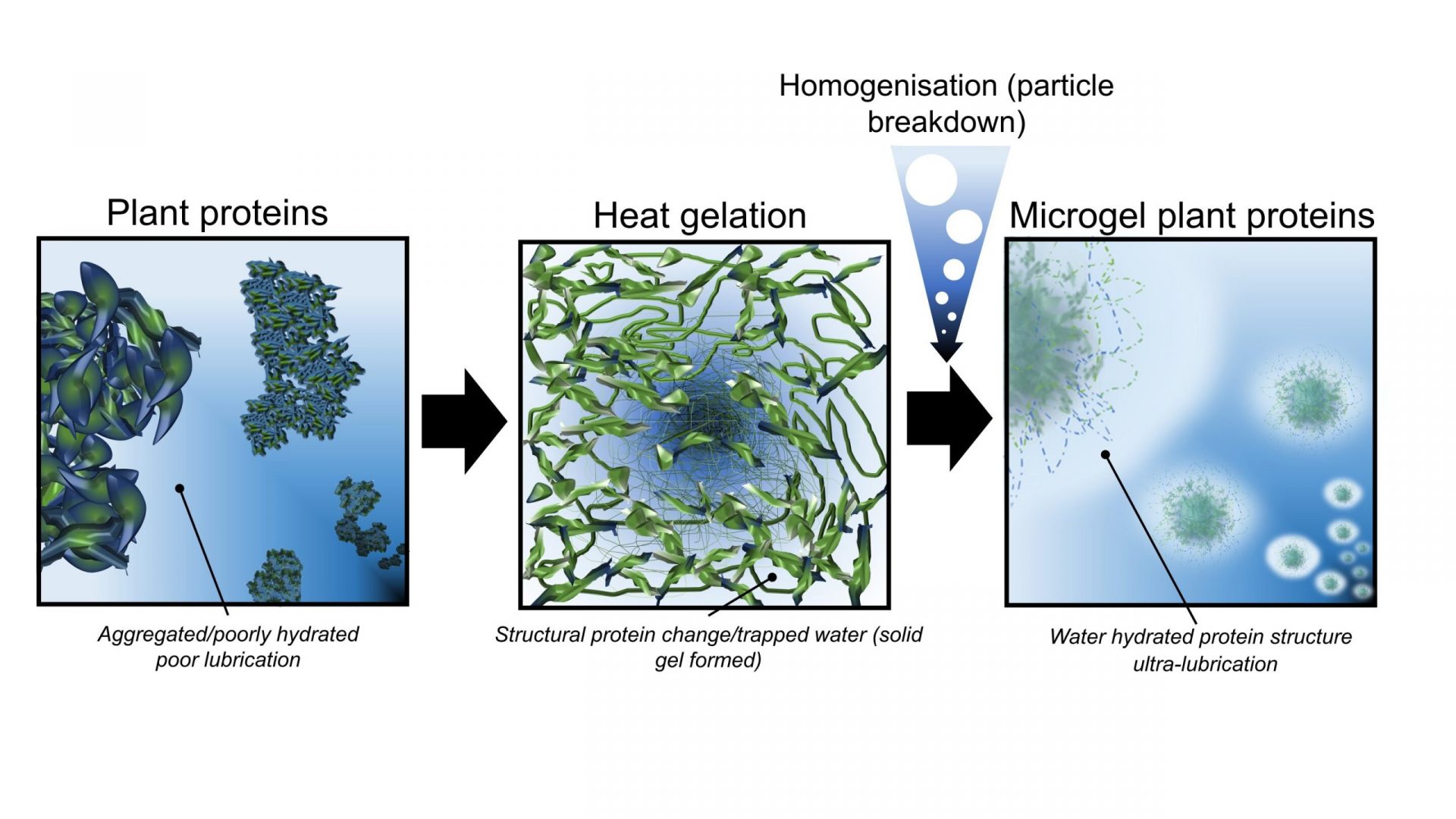

Through a process called microgeletion, the scientists created plant protein microgels. They immersed dry plant proteins in water and subjected them to heat, which altered the protein molecules’ structure. This resulted in an interconnected network or gel that trapped water around the plant proteins. The gel was then homogenized, breaking it into microgels made up of tiny particles. When pressure is applied, such as when they are eaten, the microgels release water, creating a lubricity similar to that of single cream.

Professor Anwesha Sarkar, the lead researcher, explained, “We have converted the dry plant protein into a hydrated one, using the plant protein to form a spider-like web that holds the water around it. This gives the much-needed hydration and juicy feel in the mouth. The best part is that this technique doesn’t require any added chemicals or agents, just water.”

Revitalizing Consumer Interest

The dryness of plant proteins has been a major obstacle to their widespread acceptance. However, with this breakthrough, the researchers hope to reignite consumer interest in plant-based proteins. By reducing reliance on animal products for protein intake, we can take a necessary step towards meeting global climate change targets. Currently, more than half of the carbon dioxide equivalents produced from food production come from rearing and processing animal products.

The protein microgels developed by the scientists offer a unique platform for designing the next generation of healthy, palatable, and sustainable foods.

A Eureka Moment

The research team had mathematically modeled the behavior of plant protein microgels and were confident in their approach. However, the real proof came when they visualized the microgels using atomic force microscopy. The images revealed perfectly spherical microgels that were not clumping together. Professor Sarkar expressed their excitement, saying, “Our theoretical studies had predicted this, but seeing it for real was truly amazing.”

Dr. Mel Holmes, one of the authors of the paper, highlighted the interdisciplinary nature of food science and the importance of tackling big questions through collaborative efforts.

Wider Applications of Plant Protein Microgels

Due to their lubricity, similar to that of a cream, the microgels could have various applications in the food processing industry. They could be used to replace fat in food products, creating healthier options without compromising taste and texture.

Ben Kew, the lead researcher in the project, shared their excitement, stating, “This is quite a remarkable finding. Without adding any fat, the microgels exhibit the lubricity of a 20% fat emulsion, which is unprecedented.”

The development of plant protein microgels opens up new possibilities for creating innovative and sustainable food options.